Unlock the latest in medication management technology and grow your care community with us.

Did you know?

Over 131 million Americans are using prescription medications regularly, and yet about half of them don’t follow their prescribed regimen appropriately. In such cases, the problem may not be the medication itself; it’s the packaging.

Pharmaceutical packaging plays a huge role in keeping medications safe and simple to take. As we move through 2026, pharmaceutical packaging continues to become smarter, more sustainable, and better tailored to individual needs.

At DosePacker, we’re at the forefront of this evolution, helping patients and healthcare providers navigate these changes through advanced medication management solutions.

Better Packaging Means Better Care

Let’s explore the key pharmaceutical packaging trends reshaping medication management this year.

The Rise Of Smart Packaging

Medication packaging continues to evolve with high-tech innovations. With smart features designed to enhance safety, convenience, and adherence, pharmaceutical packaging is becoming more than just a container; it’s an interactive tool.

QR Codes And NFC Tags

QR codes (Quick Response codes) and NFC (Near-Field Communication) tags are digital tools that store information and can be accessed with a quick scan using a smartphone. In pharmaceutical packaging, they provide:

- Instant access to dosage instructions, side effects, and refill options.

- Personalized reminders to take medications on time.

- Multilingual support for accessibility.

RFID And Tracking Tech

RFID (Radio Frequency Identification) tags help verify authenticity and track medications through the supply chain. These tags use radio waves to transmit data between a tag and a reader, allowing medications to be tracked throughout the supply chain.

This technology helps:

- Safely verifies prescriptions reaching patients.

- Real-time tracking to prevent theft and misplacement.

Temperature-Sensitive Packaging

To keep medications such as biologics (drugs made from living cells), insulin, and vaccines effective, pharmaceutical packaging sometimes includes built-in temperature indicators. These kinds of packaging use advanced materials, such as thermochromic inks (which change color with temperature shifts) and phase-changed materials (that absorb or release heat). These innovations ensure:

- Medications haven’t been exposed to harmful temperatures.

- Color-changing labels that alert pharmacists and patients to temperature changes.

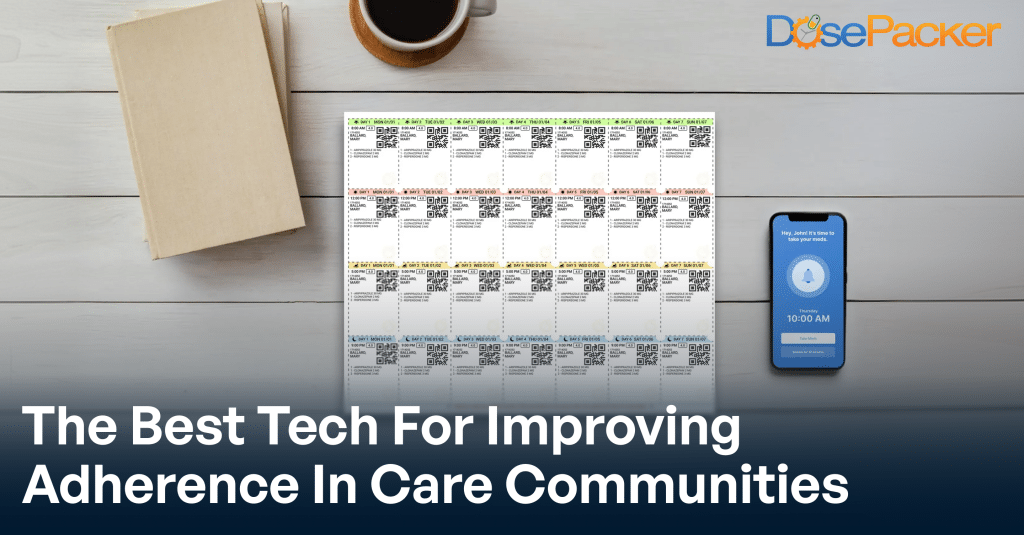

Dose-Tracking Integration

Sticking to a prescription schedule can be tough, but smart packaging is here to help! Medication adherence solutions like the MyDoses app work hand in hand with DoseMinder, a smart medication storage device, to simplify medication tracking. Together, they:

- Automate recording a dose when the patient takes it.

- Send real-time alerts and reminders through the MyDoses app to help patients stay on schedule.

- Integrate with care community management software, such as CareCommunityOS, to enable caregivers to monitor medication routines and provide timely support.

AI And Automation In Packaging Operations

Pharmaceutical packaging is getting smarter, faster, and more precise, thanks to artificial intelligence. In 2026, AI is transforming how medications are packaged, inspected, and delivered, making the entire process safer and more efficient.

Non-Contact Packaging Technology

AI-powered non-contact packaging methods protect product integrity while reducing contamination risk. This is especially critical for sterile medications, where even the slightest contamination can compromise patient safety. By minimizing human contact, these systems ensure:

- Higher sterility standards for injectable medications and biologics.

- Reduced risk of cross-contamination during packaging.

- Faster production speeds without sacrificing safety.

Automated Quality Control

Human eyes can miss defects, but AI doesn’t. Automated inspection systems for blister packs and vials now detect defects with remarkable accuracy, catching issues like:

- Cracked tablets or missing pills in blister packs.

- Foreign particles in vials or ampoules.

- Label misalignments or printing errors.

This means fewer recalls, less waste, and, most importantly, safer medications reaching patients.

Smart Demand Forecasting

AI isn’t just improving how medications are packaged; it’s also predicting what’s needed and when. AI-enhanced demand forecasting analyzes market trends and healthcare policy changes to help pharmaceutical companies:

- Anticipate supply needs before shortages occur.

- Reduce overproduction and excess inventory.

- Respond quickly to emerging health crises or policy shifts.

By combining precision, safety, and intelligence, AI is making pharmaceutical packaging more reliable than ever before.

Sustainable And Eco-Friendly Packaging

Pharmaceutical packaging industry trends are now going green. Companies are under pressure to meet global sustainability targets. By 2026, many aim to:

- Reduce packaging waste by adopting eco-friendly materials.

- Lower carbon footprints by making production and transportation more sustainable.

- Support circular-economy efforts by encouraging reuse and recycling programs.

These goals resulted in the advancement of new types of packaging solutions, such as:

Biodegradable And Recyclable Packaging

Traditional medication packaging often ends up in landfills. Many industry leaders, including DosePacker, are adopting new eco-friendly solutions, including:

- Compostable pill packs made from plant-based materials.

- Recyclable medication bottles designed for multiple use.

- Water-soluble packaging that safely dissolves after use.

Plastic Alternatives

Plastic is a major contributor to waste, and pharmaceutical companies are finding creative alternatives, such as:

- Paper-based blister packs instead of traditional plastic-and-foil designs.

- Bio-based plastics made from cornstarch, sugarcane, or seaweed.

- Glass or aluminum packaging for medications that don’t require plastic.

Minimalist Packaging

Sometimes, the best way to be sustainable is to use less packaging in the first place! Studies show that consumers are willing to pay more for sustainable packaging. As a result, the industry is shifting toward:

- Compact designs that reduce excess material.

- Blister packs made with stronger, lightweight materials reduce bulk without compromising medication protection.

- Ink and labeling innovations to reduce waste from printed inserts.

Sustainability is just one piece of the puzzle. The next step? Making packaging as personalized as the care patients receive.

Personalized Medication Packaging

Today’s packaging solutions recognize that medication adherence isn’t a one-size-fits-all challenge; it requires customized approaches for different patient needs. As a result, pharmaceutical packaging now embraces personalization. Let’s take a look at the latest innovations:

Unit-Dose And Multi-DoseCompliance

Forgetting a dose or taking the wrong one can lead to serious health risks. That’s why solutions such as DosePacker’s compliance packaging and unit-dose are gaining popularity. These solutions help by:

- Pre-sorting medications by day and time to prevent missed doses.

- Easy-open designs for seniors and those with limited dexterity.

- Clear labeling to avoid confusion, especially for multi-medication regimens.

Patient-Specific

Medication packaging tailored to specific individuals is beneficial for:

- Long-term care facilities, where staff manage multiple medications.

- Home healthcare settings, ensuring patients take the right dose at the right time.

- Pediatric and geriatric care, where special formulations or dosage adjustments are needed.

Clear And Comprehensible Labels

Individuals should be able to understand medication instructions clearly and without confusion. New trends in pharmaceutical packaging, such as those found in DosePacker’s compliance packaging, focus on enhanced accessibility with:

- Color-coded hours of administration to help patients quickly identify the right time to take their medications.

- Images of medications on the pack to reduce confusion and ensure patients know exactly which pill to take.

- Easy integration with the MyDoses app through QR codes printed on each label, allowing patients to scan and sync their medication schedule with a mobile app for reminders and tracking.

Shape the Future of Medication Packaging with DosePacker

From innovative packaging that tracks doses to eco-friendly materials that reduce waste, 2026 is shaping up to be a year of exciting innovations in pharmaceutical packaging.

At DosePacker, we combine seamless pharmacy integration with cutting-edge adherence solutions to ensure medication management delivers the best possible outcomes for everyone.

Are you ready to explore how these innovative packaging solutions can benefit your care community? Contact DosePacker today to learn more about our cutting-edge medication management systems.

Medication Management Just Got Smarter

As the industry progresses, one thing is clear: better packaging means better care. Companies that embrace these advancements improve not only their products but also patients’ lives.